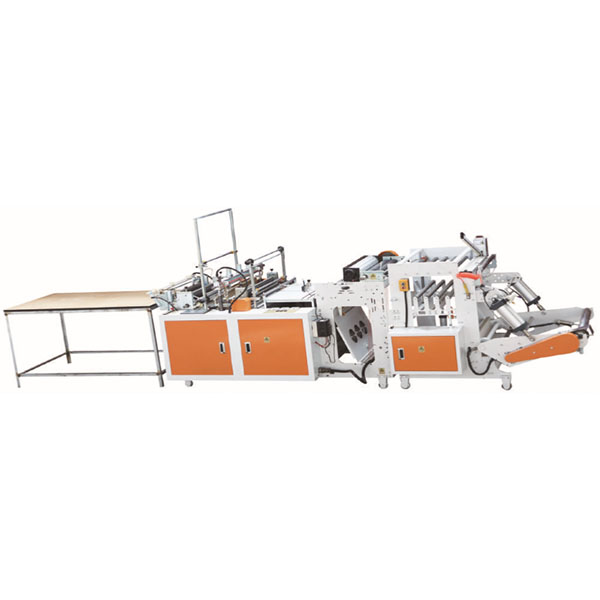

Heat Sealing And Cold Cutting Flat Bag Making Machine

1. The film of Flat Pouch Sealer with Cold Cutting is automatically supplied and adjusted automatically. There is no need to adjust the tension, and the sealing is firm and beautiful.

2. Flat Pouch Sealer with Cold Cutting uses advanced photoelectric eye tracking to ensure accurate printing pattern position.

3. Sealing and Slitting Machine for Flat Pouch Production has various automatic protection functions such as energy saving, overload, overvoltage and overcurrent.

Product Introduction Of Heat Sealing Cold Cutting Pocket Making Machine:

Sealing and Slitting Machine for Flat Pouch Production uses polyethylene and degradable material cylindrical plastic film as raw materials. Through computer control, motor feeding and photoelectric tracking, it can achieve rapid bag making and is an ideal machine for producing flat pouches.

Product Parameters Of Heat Sealing Cold Cutting Pocket Making Machine:

| Machine Type | WCJX-600-FB | WCJX-700-FB | WCJX-800-FB | WCJX-400×2-FB | WCJX-500×2-FB | WCJX-600×2-FB | |

| Machine Components | Main machine | Main machine | Main machine | Main machine | Main machine | Main machine | |

| Bag Making Length(mm) | ≤1200 | ≤1500 | ≤1500 | ≤800 | ≤1000 | ≤1200 | |

| Bag Making Width(mm) | 200-550 | 300-650 | 300-750 | 100-300 | 100-400 | 150-500 | |

| Bag Making Thickness(mm) | 0.02-0.15 | 0.02-0.15 | 0.02-0.15 | 0.02-0.15 | 0.02-0.15 | 0.02-0.15 | |

| Bag Making Speed(pcs/min) | PE Flim | 30-200 | 30-200 | 30-200 | (30-260)×2 | (30-240)×2 | (30-200)×2 |

| PBAT/PLA Flim | 30-150 | 30-150 | 30-150 | (30-200)×2 | (30-200)×2 | (30-150)×2 | |

| Pressure Range(MPa) | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 | 0.2-0.6 | |

| Total Power(KW) | 11 | 11.5 | 12 | 15 | 16 | 17 | |

| Power Source(V/Hz) | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | 380/50 | |

| Machine Weight(Kg) | 1200 | 1300 | 1400 | 1600 | 1700 | 1800 | |

| Packing Dimension(LXWXH)(mm) | Unwinding Frame | 1000×1000×1260 | 1000×1100×1260 | 1000×1200×1260 | 1000×1420×1260 | 1000×1620×1260 | 1000×1720×1260 |

| Main Machine | 2300×1230×1790 | 2300×1330×1940 | 2300×1430×1940 | 2300×1570×1790 | 2300×1770×1790 | 2300×1970×1790 | |

| Overall Dimension(LXWXH)(mm) | 3745×1230×1785mm | 3745×1330×1935mm | 3745×1430×1935mm | 3745×1570×1785 | 3745×1770×1785 | 3745×1970×1785 | |

Product Advantages Of Heat Sealing Cold Cutting Pocket Making Machine:

1. The Sealing and Slitting Machine for Flat Pouch Production has accurate sealing and cutting accuracy, the feeding rubber roller and the anti-stretch rubber roller run synchronously, and it is not easy to stretch and has high stability;

2. Flat Pouch Sealer with Cold Cutting has the characteristics of smooth operation, stable sealing, low noise, and energy saving.

3. Flat Pouch Sealer with Cold Cutting can automatically count and set a fixed length arbitrarily. This machine also has functions such as automatic alarm, shutdown and restart, and has a high safety index.

Enterprise Strength:

Yingkou Wancheng Machinery Co., Ltd. is an enterprise that integrates independent research and development, production and sales of plastic bag making equipment. It has its own factory area of 6,000 square meters and more than 60 employees. It has multiple complete sets of plastic processing machinery and equipment production groups. , after continuous operation, various models of Flat Pouch Sealer with Cold Cutting produced by our company are sold all over the world. Our company has always focused on the sales of products on the Internet platform, and welcomes new and old customers to inquire and order.