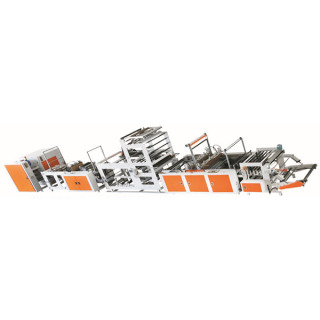

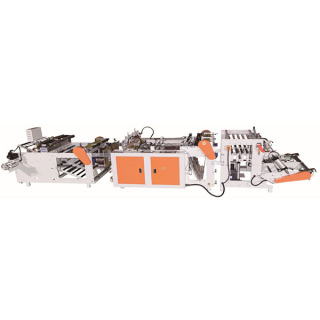

Double Lines Cored Rolling Bag Making Machine

1. The motor of the Twin core rolling bag making machine has high power, fast cutting speed, and can realize continuous automatic work.

2. The raw materials of the Twin core rolling bag making machine are of high quality, and the service life is longer and more stable.

3. The sealing of the Double line core rolling bag making machine is smooth, the texture is clear, and the product is simple and beautiful.

Product Uses Of Twin Core Rolling Bag Making Machine:

The Double lines core rolling bag making machine has efficient and precise production capabilities and can be used to process cylindrical films made of PE and degradable materials. The Double line core rolling bag making machine is controlled by a computer and uses heat sealing and cold cutting technology to achieve tooth-cutting points. The alternating operation of cutting and sealing copper knives completes the high-quality production of products.

Product Parameters Of Twin Core Rolling Bag Making Machine:

| Machine Type | WCJX-450×2AC-RB | ||

| Machine Components | Main Machine | Auto Roll-change Auxiliary Machine | |

| Bag Making Length(mm) | ≤800 | ||

| Bag Making Width(mm) | 200-400 | ||

| Bag Making Thickness(mm) | 0.008-0.15 | ||

Bag Making Speed(pcs/min) | PE | (50-300)×2 | |

| PBAT | (50-200)×2 | ||

| Roll-change Speed(times/min) | 5 | ||

| Pressure Range(Mpa) | 0.2-0.6 | 0.4-0.6 | |

| Total Power(KW) | 12 | 8 | |

| Power Source(V/Hz) | 380V/50Hz | 220V/50Hz | |

| Machine Weight(Kg) | 1500 | 1500 | |

Packing Dimension(L×W×H)(mm) | Unwinding Frame | 1000×1520×1260 | 1100×2620×1600 |

| Main Machine | 2120×1670×1360 | ||

| EPC Auxiliary Frame | 1760×1450×1050 | ||

| Overall Dimension(L×W×H)(mm) | 6580×2620×1600 | ||

Product Advantages Of Twin Core Rolling Bag Making Machine:

1. The Automatic Dual Garbage Bag Roll Making Machine uses a high-power feeding motor and is equipped with a deviation correction system to achieve uniform and stable feeding.

2. The Double lines core rolling bag making machine has a rigorous production process, high cutting precision, and stable performance; it can increase production capacity and increase output by replacing auxiliary machines.

3.Automatic Dual Garbage Bag Roll Making Machine uses electric eye tracking to achieve accurate positioning. It can independently set the bag length, production speed, and operation time; it is easy to operate and improves work efficiency.

Enterprise Strength:

Our products include hot-cut, cold-cut, continuous coil and other series, with an output of 600 sets/year. We continue to improve our research and development production technology and strictly test each process. Our products comply with national standards. If you need it, you can contact us. We will provide you with comprehensive technical support.