1. The Vest bag making machine adopts microcomputer control and photoelectric tracking of color printing steps, which can operate stably and continuously at high speed for a long time.

2. The speed of the Vest bag making machine is adjustable, the temperature is controllable, and the sealing is firm, smooth and simple.

3. The Vest bag making machine has a novel structure, reliable performance, simple operation and high degree of automation.

1. Single Line Bag on Roll Machines have strong functionality, reasonable structure, safe operation, and wide application fields.

2. The Single Line Roll Bag Making Machine is fully automatic from bag making to soft sealing, with high sealing positioning accuracy and smooth feeding.

3. The Single Line Roll Bag Making Machine adopts a software control system, making the sealing and cutting operation more stable and precise, and the bag mouth is firm and round.

1. Heat sealing Cold cutting pocket making machine can automatically load materials and be controlled by computer to reduce manpower and improve production efficiency.

2. Heat sealing Cold cutting pocket making machine has the function of delivering bags without overlapping heat sealing lines, and there is no adhesion between sealing lines.

3. After the count of Heat sealing Cold cutting no tension bag making machine arrives, the collection table automatically shifts to facilitate packaging.

1. Two Color 4 Lines Flexo Plastic Bag Printer can perform pneumatic punching and online punching, with high production efficiency; high power, high output, and stable operation for a long time.

2. The Two Color 4 Lines Flexo Plastic Bag Printer has a high degree of automation. It can complete feeding, back sealing, cutting and punching at one time, which improves economic efficiency.

3. The parameters of the Two Color 4 Lines Flexo Plastic Bag Printer are adjustable. The machine automatically counts and stops automatically when reaching the set value, reducing labor intensity.

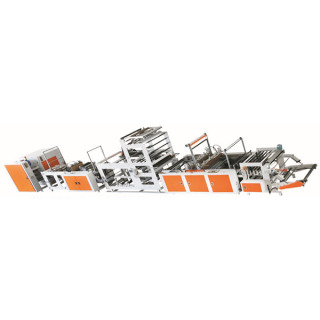

1. Quadruple Line Bag Maker uses a pneumatic punching device and online punching and clamping to improve accuracy and efficiency.

2. Quadruple Line Bag Maker can be fully automated and completed in one go, saving manpower and time.

3. Quadruple Line Bag Maker uses photoelectric tracking, which is highly accurate, and the motor is fixed in length, accurate and stable.

1. The feeding rubber rollers and anti-stretch rubber rollers of the flat bag manufacturing and folding conveyor machine run synchronously, and the sealing is firm and beautiful without stretching.

2. Flat bag manufacturing and folding conveyor machine can realize synchronous automatic labeling, with precise position and stable performance.

3. Flat bag manufacturing and folding conveyor machine can feed materials at high speed and is controlled by microcomputer with a high degree of automation.

1. Automatic Flat Pouch Maker with Heat Cold Cut is equipped with automatic counting and alarm devices to reduce labor costs and improve production efficiency.

2. Automatic Flat Pouch Maker with Heat Cold Cut is capable of optical eye tracking, accurate positioning, and can automatically stop when errors occur.

3. The parameters of Automatic Flat Pouch Maker with Heat Cold Cut are adjustable, such as bag making length, speed, temperature, etc.

1. Heat Sealing Heat Cutting Poly Bag Machine has a user-friendly structural design, which can quickly transport materials and realize automatic stacking of bags, making it convenient for collection and packaging.

2. Heat Sealing Heat Cutting Poly Bag Machine is capable of high-speed conveying and precise positioning; intelligent operation greatly reduces labor intensity.

3. Heat Sealing Heat Cutting Poly Bag Machine adopts pneumatic punching device and online punching and clamping, saving intermediate links and improving production efficiency.

1. The cutting blade of the Computer Control Rolling Plastic Bag Making Machine is sharp and durable, with smooth cuts and no burrs.

2. Computer Control Rolling Plastic Bag Making Machine can realize fully automatic feeding, with strong feeding, stable cutting and easy movement.

3. Computer Control Rolling Plastic Bag Making Machine adopts high-performance motor, which is resistant to high temperature, wear and tear and has excellent performance.

1. The motor of the Twin core rolling bag making machine has high power, fast cutting speed, and can realize continuous automatic work.

2. The raw materials of the Twin core rolling bag making machine are of high quality, and the service life is longer and more stable.

3. The sealing of the Double line core rolling bag making machine is smooth, the texture is clear, and the product is simple and beautiful.

1. Fully automatic rolling bag making machine is mainly used to process rolling flat bags with high production efficiency.

2. Fully Automatic S shape garbage bag on roll making machine can realize fully automatic feeding, saving labor and stable working status.

3. Automatic S shaped rolling bag production machine adopts electric eye tracking, which has accurate positioning and can automatically correct deviations.

1. Interleave s type bag making machine has high folding accuracy, no need for manual sorting, accurate feeding, and no material interruption.

2. The Interleave s type bag making machine is precisely controlled by computer, making the operation convenient and worry-free.

3. Interleave s type bag making machine has good safety performance and is sensitive and stable during the production process.